Recognizing Gear Failure Due To Wear

Are The Gears Starting To Wear Down?

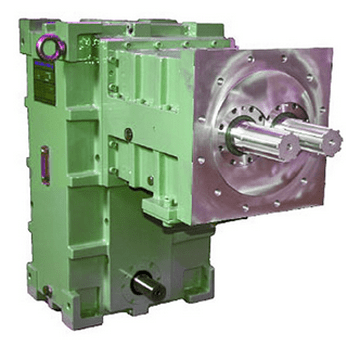

Gears play an important role in industry, acting as a basic component of a gearbox. The latter is essential industrial equipment which transmits mechanical power.

Gears play an important role in industry, acting as a basic component of a gearbox. The latter is essential industrial equipment which transmits mechanical power.

In principle a gearbox helps produce a much greater rotation from a relatively small rotation force (torque). This allows the equipment to increase the rate of revolution. Various manufacturing and processing industries depend on gears and gearboxes for a range of applications.

This reflects how a gearbox failure can result in downtime and affect productivity. Breakdown of a gearbox is most often a result of damage to either gears or bearing. Hence you should pay particular attention to these components during inspection and maintenance.

Gear Failure Due To Wear

Damage due to wear is the most frequently occurring cause of gear failure. Since gears are heavily used in industry, they are bound to suffer wear related damage over the course of operation.

Since the damage occurs while gears are ‘doing their job’, it’s hard to prevent it. However, gear failure as a result of damage can be avoided, if timely repairs are made. However, you must be able to identify gear damage that can occur because of wear.

Moderate wear: It is the most common wear related failure. This mainly occurs because of lubricant contamination. Other causes can include gear speed, limitations of lubricant viscosity and temperature.

Abrasive wear: These are characterized by appearance of scratch marks on the surface of gear teeth. It is the most noticeable visual sign of abrasive damage. In some cases, the scratch marks may be confused as signs of Micropitting because they look very similar.

It is caused because of the metal particles present in the gears and bearings, rust, sand, weld spatter, scale and dirt in the gear lubricant.

Corrosive wear: As it is apparent by the name, this type of damage occurs because of the corrosive action of various parts and substances on gear teeth. It can be visually inspected as spotty dots which appear scattered over gear teeth.

There are three common cause of this type of wear damage:

1. Chemical action of various ingredients of the lubricant such as acids

2. Presence of foreign materials and moisture in the lubricant

3. And, extreme pressure additives which are added to the lubricant reacting with gear teeth

Scuffing damage can also appear on gear teeth if gears are operated without adequate amount of lubricant, or if its viscosity is low. Ripples on contacting surface of the gear teeth are visible in this condition.

These problems can only be avoided to an extent by using a proper lubricant of adequate viscosity and free of contaminants. However, like other machines and their components, life of gears and gearboxes can be extended through timely repairs.

Our expert engineers offer gear grinding and repair services to assist you in maintaining the gears in top condition. If the gearbox is continuously faulting or has gone through repairs multiple times, consider buying a new model. Our gearbox rebuilding and manufacturing services are just a call away!

Read More Posts