Blown Film Die Repair Service

With over six decades of expertise, we stand as a comprehensive industrial equipment repair and rebuilding hub, providing round-the-clock blown film die repair services across the nation. Our all-encompassing approach ensures seamless solutions for your needs.

The Nations #1 Blown Film Die Repair Facility

We're a full-service, all-in-one industrial equipment repair and rebuilding facility that offers 24hr, nationwide blown film die repair services with 60+ years of experience!

Electroless Nickel Mirror Finish Polishing High Precision OD/ID Grinding

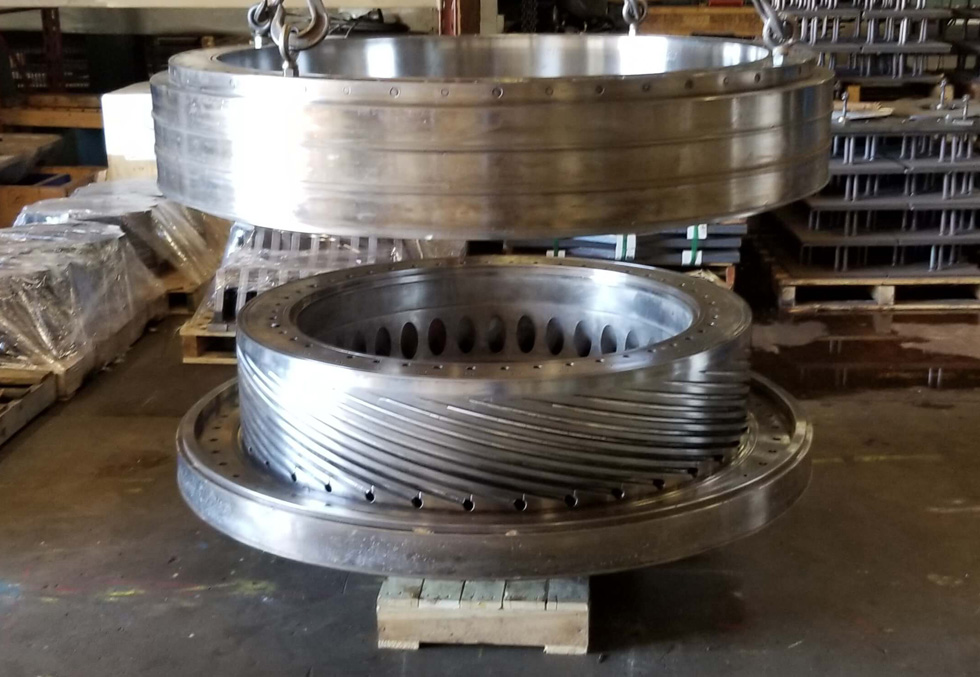

We have the experience, the equipment, and the technology to get your dies back up and running quickly and efficiently.

We offer a wide range of Blown Film Die Services, including:

- Cleaning

- Burning

- Repairing

- Rebuilding

- Hard chrome plating

- Electro-nickel plating on every make and model of blown film dies, rings, pins, spirals bodies, shafts, heads, cylinders, pistons, mandrels housings, screws, plate molds & many more.

Virtually Every Part in Stock Inventory of 0ver 18,000 parts!

We are specializing in:

- Davis Standard

- Egan

- Gloucester

- EDI

- Santo

- Alpine

- Battenfeld

- Hartig

- Krupp

- Graham

- Black Clawson

- Brampton & many more

Blown Film Die Servies

We offer a wide range of services including:

- Sizing pin & ring adjustments

- Complete rebuilds

- Rebuild and refinish of all major brands of industrial blown film dies

- Repair of extruder screws

- Repair of air rings

- Repair of blown film extrusions

- Manufacture of brand new film dies

Top Quality Surface Plating & Polishing Options

Hard Chrome Solutions offers a wide range of polishing and surface finishes on blown film dies, extruder screws, and air rings. Surfaces available include various roughnesses of precision ground rolls as well as commercial belt polished finishes.

Finishing options include:

- Custom Chromium Finishes

- Mirror

- Optical Mirror

- Matte

- Satin

With our proficient team and extensive range of cutting-edge equipment and emerging technologies, Hard Chrome Solutions stands as a blown film die repair facility proficient in managing diverse machining and chrome plating tasks. Our plating and repair solutions offer exceptional operational efficiency, adaptability, and dependability. We possess the ability to reconstruct and enhance industrial blown film dies, extruder screws, air rings, blown film extrusions, and a host of other major brands. Additionally, we are adept at crafting entirely new film dies.

By blending expertise with state-of-the-art machinery, we are empowered to craft components for our clients with heightened precision and effectiveness, adhering meticulously to their desired surface standards and specifications. Those seeking blown film die repair services can anticipate swift delivery of components, coupled with competitive pricing, underscoring our commitment to efficiency and value.

Select HARD CHROME SOLUTIONS as your destination for blown film die repairs, and allow us to instill your trust through our hands-on technical assistance and our commitment to delivering repairs of the highest caliber within a prompt timeframe.