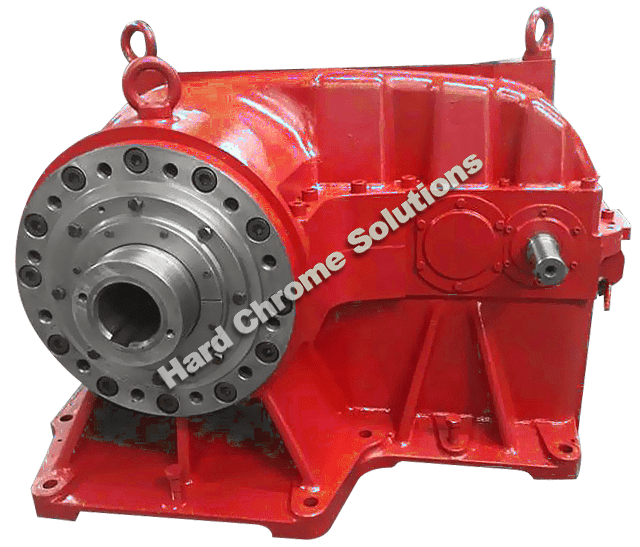

Extruder Gearbox Repair Service - 24hr Emergency Services

Full-service Extruder Gearbox Services: Repairs, Rebuilds & Upgrades

Hard Chrome Solution is your one stop for Gearbox repair, including reliable, responsive Gear drive inspections, overhauls and upgrades

Hard Chrome Solutions specializes in extruder gearbox repairs, rebuilds, and redesigns. With over six decades in this business, we've seen almost every type of extruder gear challenge across a wide variety of markets and applications. We offer comprehensive turnkey solutions for all your gearing needs, and have the experience to know exactly what to recommend for your gearing application from small repairs to complete rebuilds.

Our incredibly talented team of German trained engineers and dedicated professionals focus their unique skills to design your gear and extruder gearbox repairs, rebuilds, and upgrades that will exceed your current process loads. Our solutions usually result in rebuilt extruder gearboxes that are stronger, deliver higher torque & output, reduce downtime and save money on future repairs.

We repair, re-engineer and sometimes re-invent your gearing with the latest engineering technology that makes it better than the original.

Hard Chrome Solutions specializes in extruder gearbox repairs, including:

These are merely a selection of the numerous gearboxes, shafts, rollers, and pumps that we have expertise in repairing.

- Allen Gears Gearbox Repair

- Alpine Gearbox Repair

- Alstom Gearbox Repair

- Alten Pump Drives Gearbox Repair

- Amarillo Pump Drives Gearbox Repair

- American Kuhne Gearbox Repair

- Baker Hughes Gearbox Repair

- Baker Perkins Gearbox Repair

- Banbury Mixer Gearbox Repair

- Battenfield Gearbox Repair

- Baumuller Nurnberg Gearbox Repair

- Begum Gearbox Repair

- Beringer Gearbox Repair

- Berlyn Gearbox Repair

- Berstorff Gearbox Repair

- Black Clawson Gearbox Repair

- Bliss Gearbox Repair

- Bonfiglioli Gearbox Repair

- Brampton Gearbox Repair

- Browning Speed Reducers Gearbox Repair

- California Pellet Mill Gearbox Repair

- Camco Ferguson Gearbox Repair

- Chicago Gears Gearbox Repair

- Cincinnati Milacron Gearbox Repair

- Cleveland Worm Drives Gearbox Repair

- Cone Drives Gearbox Repair

- Conveyor Gearbox Repair

- Cooling tower Gearbox Repair

- Coperion Gearbox Repair

- Criton Planetary Gearbox Repair

- Crown Gearbox Repair

- David Brown Gearbox Repair

- Davis Standard Gearbox Repair

- De’Ran Gearbox Repair

- Delaval Steam Turbine Gearbox Repair

- Delroyd Worm Gearbox Repair

- Diamond America Gearbox Repair

- Dodge Reliance Electric Gearbox Repair

- Dorris Gearbox Repair

- Dover Gearbox Repair

- Drive All Gearbox Repair

- Durramax Gearbox Repair

- Eagle Iron Works Gearbox Repair

- Eaton Gearbox Repair

- Egan Gearbox Repair

- Eisenbeiss Gearbox Repair

- Entwistle Gearbox Repair

- Epicyclic Drive Units Gearbox Repair

- Extruder Extrusion Gearbox Repair

- Falk Gearbox Repair

- Farrel Gearbox Repair

- Fessler Gearbox Repair

- Flender Gearbox Repair

- Flender Graffenstaden Gearbox Repair

- Foote Jones Gearbox Repair

- Ge Gearbox Repair

- Gloucester Gearbox Repair

- Gnuess Gearbox Repair

- Graham Engineering Gearbox Repair

- H and S Gearbox Repair

- H Gearbox Repair

- Hamilton Gearbox Repair

- Hansen Gearbox Repair

- Harnischfeger Crane Gearbox Repair

- Harrel Gearbox Repair

- Hartig Gearbox Repair

- Henschel Durum Gearbox Repair

- Henschel Gearbox Repair

- Hitachi Caster Gearbox Repair

- Horsburgh & Scott Gearbox Repair

- Jupiter Gearbox Repair

- Killion Gearbox Repair

- Kissling Gearbox Repair

- Koellmann Gearbox Repair

- Konecranes Gearbox Repair

- Krauss Maffei Gearbox Repair

- Kreyenborg Gearbox Repair

- Krupp Gearbox Repair

- Leistritz Gearbox Repair

- Liebherr Gearbox Repair

- Lightnin Gearbox Repair

- Link Belt Gearbox Repair

- Lohmann Gearbox Repair

- Lohmann Planetary Drives Gearbox Repair

- Lufkin Gearbox Repair

- Maag Gearbox Repair

- Maplan Gearbox Repair

- Marley Gearbox Repair

- Mclanahan Gearbox Repair

- Merritt Gearbox Repair

- Milwaukee Gearbox Repair

- Mixer Gearbox Repair

- Morse Gearbox Repair

- Neptune Gearbox Repair

- NFM Gearbox Repair

- Nord Gearbox Repair

- NRM Extruder Gearbox Repair

- NRM Gearbox Repair

- Nuttall Gearbox Repair

- Philadelphia Mixer Gearbox Repair

- PIV Brevini Gearbox Repair

- Piv Drive Gearbox Repair

- Planetary Gearbox Repair

- Pollack Bottle Car Gearbox Repair

- Polytruder Gearbox Repair

- Prodex Gearbox Repair

- PSI Gearbox Repair

- PTI Gearbox Repair

- Raymond Mill Gearbox Repair

- Renk Gearbox Repair

- Renold Gearbox Repair

- Santasalo Gearbox Repair

- Saturn Gearbox Repair

- Sew Eurodrive Gearbox Repair

- Sieman Gearbox Repair

- Sterling Gearbox Repair

- Sumitimo Cylco Gearbox Repair

- Sumitomo Paramax Gearbox Repair

- Symetro Gearbox Repair

- Terex Comedil Gearbox Repair

- Thyssen Gearbox Repair

- Titan Gearbox Repair

- Toshiba Gearbox Repair

- Voeller Gearbox Repair

- Welding Engineers Gearbox Repair

- Welex Gearbox Repair

- Werner & Pfleiderer Gearbox Repair

- Westech Gearbox Repair

- Western Gearbox Repair

- Westinghouse Gearbox Repair

- Winsmith Gearbox Repair

- Zahnradfabrik Friedrichshafen Gearbox Repair

- Zambello Gearbox Repair

Our Full Range Of Repair Services Includes:

- Emergency Breakdowns

- Removal of Equipment

- Installation and Start-up

- Laser Alignment

- Performance Testing

- Fault Diagnostics

- Gearbox Systems

- Twin Extruders Repair, Rebuilding & Troubleshooting

- Single Screw Gearbox Systems Repair & Troubleshooting

- Conical Gearbox Systems Repair & Troubleshooting

- Pumps & Blowers Repair, Rebuilding & Troubleshooting

- Rolls Repair, Rebuilding & Troubleshooting

- Screw and Barrels Repair, Rebuilding & Troubleshooting

- Cutting Equipment Repair, Rebuilding & Troubleshooting

- Custom Gear Manufacturing Repair, Rebuilding & Troubleshooting

Our repair philosophy is simple:

- We repair your equipment to original factory specifications or industry standards.

- We do it in a timely fashion. And we do it right the first time.

- Extruder and Extruder Gearbox repair services are geared towards substantially minimizing your downtime, allowing your processes to run smoothly for extended periods.