Film Dies And Air Rings

Setting Up Blown Film Dies And Air Rings

Producing film through extrusion of molten resin in a continuous tube can look very simple. The design and technology has certainly improved over years. However, it is a very complex process which requires care and precision.

Producing film through extrusion of molten resin in a continuous tube can look very simple. The design and technology has certainly improved over years. However, it is a very complex process which requires care and precision.

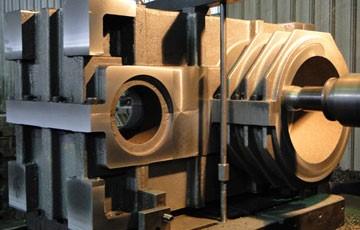

As repair and rebuilding service providers, we offer emergency services for blown films and air rings. Multiple elements are involved in the design—which is made more efficient and precise by our technicians to suit your industrial applications!

Setting up these dies and air rings in the correct configuration is very important. Here is how we ensure it’s done the right way:

1. The die should be maintained in the center underneath the main nip roll assembly. The plumb line which is dropped from the nips should not be further out than the edge of a dime which is placed in the center of die face.

If the die is from another line or is new with an incorrect adapter length, then obtaining a true plumb line will be a problem. If the die is extremely off-center, it will be highly distorted too. This will result in both wrinkles and poor gauge which can’t be corrected by the operator.

2. The top of the die must be leveled after both die and extruder have reached the operating temperature. The barrel clamps must also be tightened to the adapter and all casters should be in contact with the floor.

2. The top of the die must be leveled after both die and extruder have reached the operating temperature. The barrel clamps must also be tightened to the adapter and all casters should be in contact with the floor.

The die can’t be leveled separately because most floors are not leveled, distance between floor and die adaptor increases varyingly, and vibration occurs if any of the casters are not firmly in contact with the ground.

3. The ring can only be leveled and centered once the die is properly leveled. The air die is often not fastened to the top edge of the die. It is instead dependant on its own weight for holding in position.

A good operator will always check the air ring center and level if the bubble is down. If it’s up, it will be impossible to know whether ring or the die needs any adjustment.

4. Following the leveling, a few air rings are set on top of the die on a flame retardant pad. Other air rings are instead raised above the top with an air gap providing insulation.

5. The air ring is often less sensitive to top opening adjustments and blower if an air gap exists between the top of the die and the air ring. However, this means that airflow is present between the top of the die and the bottom of the ring that impinges the hot melt as it is extruding from the die.

Dirt, silicone grease and pieces of purge in the open space will disturb this air flow, resulting in gauge bands infiltrating the film.

It can be rather complex to ensure the correct setup but is necessary. We offer repairing, rebuilding and plating services for all models of blown film dies and air rings, with the inclusion of centrifuge rebuilding and gearbox upgrade services.

You can also call us for 24/7 emergency services. We make sure you have the right surface qualities and other specifications for your application!

Read More Posts